We use cookies to understand how you use our site and to improve your experience. This includes personalizing content and advertising. By continuing to use our site, you accept our use of cookies. View our Privacy Statement.

OUR PRODUCTS

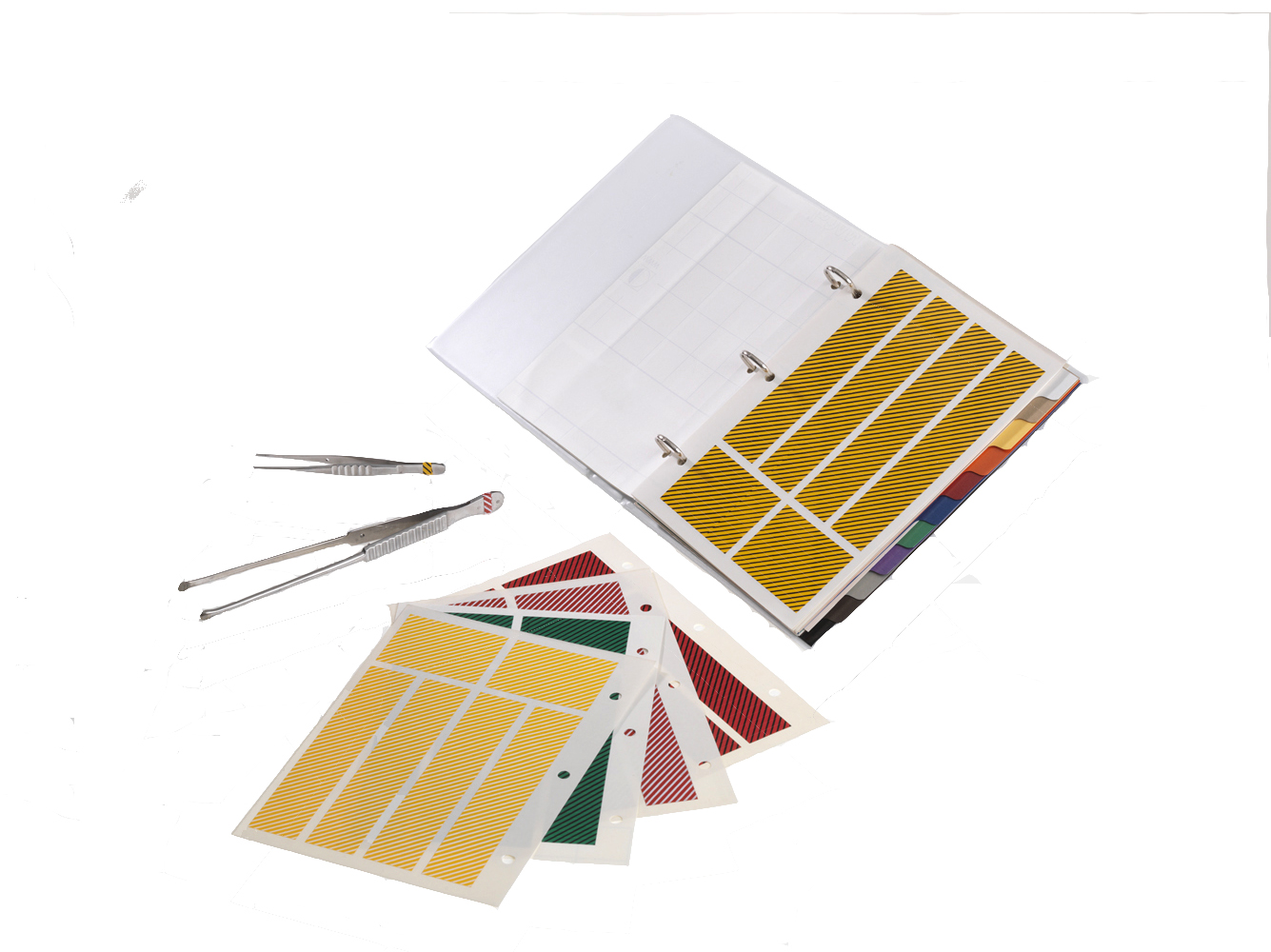

CSSD

Operating Theatre

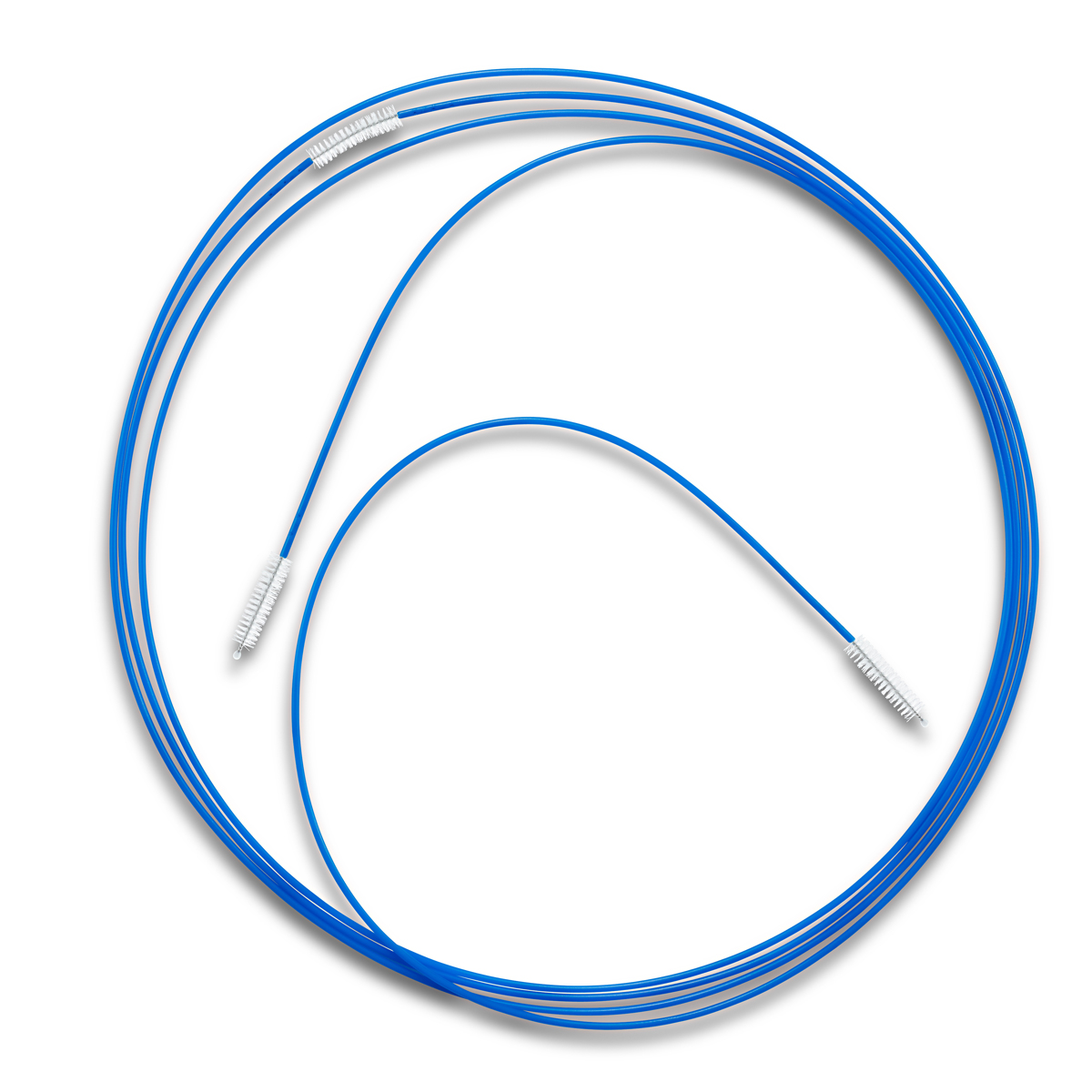

Endoscopy

News and Events

Upcoming Events

No Upcoming Events

.jpg?width=1200&height=1200&ext=.jpg)

_1.jpg?ext=.jpg)

.jpg?ext=.jpg)